- The Cost of Downtime in the Rental World

- What Predictive Maintenance Means for Rental Businesses

- From Reactive to Predictive: A Shift in Approach

- How AI Detects Issues Before They Cost You

- The ROI of Predictive Maintenance

- Real-World Example: Smarter Servicing in Action

- How to Get Started with Predictive Maintenance

- Overcoming Common Barriers

- The Bigger Picture: Connected Intelligence

- The Takeaway: From Breakdowns to Breakthroughs

The Cost of Downtime in the Rental World

Every minute a piece of equipment sits idle, your revenue stalls. For rental businesses managing hundreds of assets—from excavators and generators to AV lighting and staging gear—unexpected breakdowns ripple across operations.

We’ve seen this firsthand across rental teams we work with. It’s rarely one big failure that hurts—it’s dozens of small preventable issues that compound: a late repair here, a missed note there, a filter overdue by two days.

Traditionally, maintenance has been reactive: fix it when it breaks. Some companies have moved to preventive maintenance—scheduled service every few months or rentals—but that often leads to unnecessary downtime or missed issues.

Across the rental software industry, leaders are recognizing that reactive maintenance is no longer sustainable. The future is predictive—driven by data, powered by AI, and proven to cut downtime by as much as 50%.

What Predictive Maintenance Means for Rental Businesses

Predictive maintenance uses artificial intelligence and machine learning to anticipate equipment failures before they happen.

At TapGoods, we think about this as visibility—turning all those scattered maintenance logs and gut feelings into clear, data-driven signals. You can’t prevent what you can’t see.

By combining data on rental frequency, load, and conditions, AI identifies patterns invisible to humans.

Recent studies show AI models can analyze vibration or oil sensor data to forecast mechanical wear up to ten days before a visible failure, enabling earlier intervention and lower costs.

As reported by Harvard Business Review, predictive-maintenance models across manufacturing and logistics industries have significantly reduced downtime and operational risk.

Of course, not every rental company has telematics or IoT sensors—and that’s okay. Even something as simple as tracking high-usage assets in your rental software creates a foundation for smarter scheduling.

From Reactive to Predictive: A Shift in Approach

| Approach | Description | Common Pitfalls |

|---|---|---|

| Reactive Maintenance | Equipment serviced only after failure | Costly downtime, emergency repairs, safety risks |

| Preventive Maintenance | Regular, schedule-based service (for example, every 90 days) | Can waste time or overlook hidden issues |

| Predictive Maintenance (AI-Driven) | Data-driven insights predict when failure will occur | Proactive repairs, reduced costs, extended lifespan |

One of our Texas-based clients used to run on strict calendar-based intervals. When they shifted to usage-based service, they realized nearly 40% of those “routine” jobs were unnecessary—burning both labor and parts budgets.

How AI Detects Issues Before They Cost You

AI systems continuously analyze performance data to uncover subtle shifts that precede breakdowns.

We’ve seen that the most valuable signals don’t always come from sensors—they come from your own rental data. A spike in short-term repeat rentals or a drop in check-in condition scores can be early red flags long before a machine fails.

In other words, AI is like the technician who’s seen it all—but with the memory of 10,000 jobs instead of ten.

Studies from MultiSensor AI highlight how advanced algorithms detect anomalies before human technicians can spot them—providing another layer of early warning that keeps equipment in rotation and downtime to a minimum.

The ROI of Predictive Maintenance

AI-driven maintenance doesn’t just prevent headaches—it boosts profitability.

In our internal TapGoods client analyses, we’ve found that even modest predictive scheduling—just prioritizing top earners for early maintenance—can lift monthly utilization by 8-10%.

According to research by McKinsey & Company, organizations using predictive maintenance can reduce unplanned downtime by up to 50% and maintenance costs by 10–40%.

Those numbers are big, but what stands out to me isn’t the savings—it’s the consistency. Predictive maintenance flattens the chaos. You plan, instead of react.

Real-World Example: Smarter Servicing in Action

Imagine your company operates 300 diesel generators. Historically, your service team replaced filters every 200 hours of use. But analysis reveals that failures spike after 150 hours if those units were rented out consecutively in high-temperature regions.

Using AI, the system flags those specific generators for early service, while others remain on normal intervals—cutting unnecessary maintenance by 20% while preventing mid-rental breakdowns.

One of our rental partners experienced something similar after a summer heat wave pushed their generators to the limit. Once they started tracking load averages, their repair backlog virtually disappeared.

How to Get Started with Predictive Maintenance

You don’t need sensors on every asset to start applying AI thinking today.

Start with what you already have. Your order history, service logs, and item utilization reports are gold mines of predictive signals waiting to be tapped.

Here’s how to begin:

- Centralize your equipment data.

Consolidate records from service logs, rental software, and spreadsheets. AI thrives on unified, consistent data.

- Track usage and utilization rates.

Focus on hours, conditions, and rental frequency—not just counts.

- Prioritize high-value assets.

Start with items that cost the most to replace or fail most often. Early wins build buy-in. - Choose a platform with built-in intelligence.

Integration is key: AI should live within your rental software, not as a separate tool.

Overcoming Common Barriers

| Challenge | How to Solve It |

|---|---|

| “Our data isn’t clean enough.” | Begin anyway. Even partial data sets teach models valuable patterns over time. |

| “Technicians don’t trust AI.” | Show early success metrics—when AI predicts a near-miss, celebrate it. |

| “Too expensive to implement. | Start with pilot assets; most AI tools scale affordably once the model learns. |

| “Our systems don’t talk to each other.” | Use software with open APIs or built-in AI like TapWise to avoid silos. |

The Bigger Picture: Connected Intelligence

Predictive maintenance is one pillar of an AI-driven rental operation. Once your maintenance data is structured, you can extend those same insights to:

- AI demand forecasting – predict peak months and pricing opportunities

- Dispatch optimization – streamline routes for technicians and deliveries

- Customer experience insights – identify repeat renters and offer tailored packages

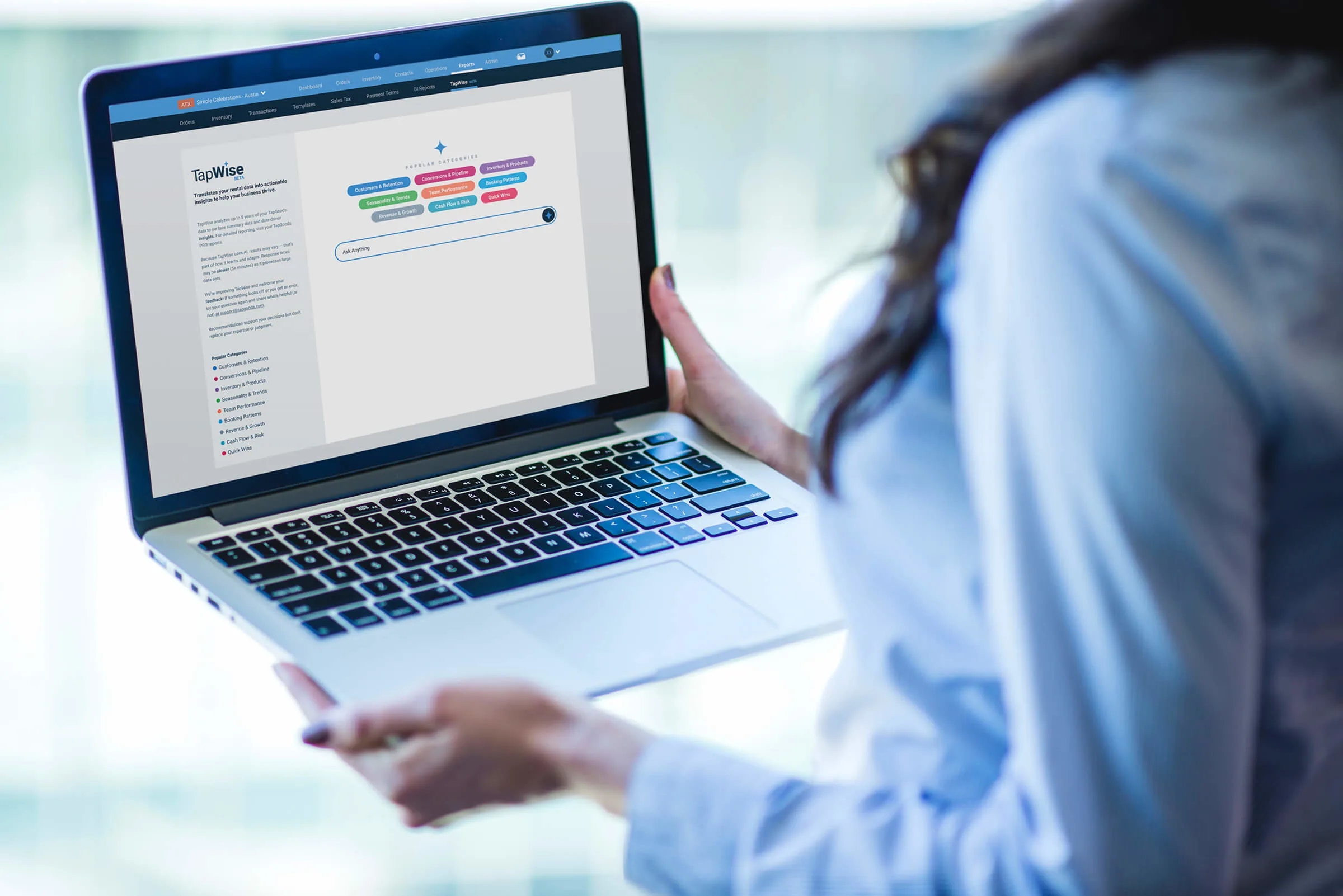

That’s the philosophy behind TapWise: you shouldn’t have to become a data scientist to run a data-driven business. AI should meet you where you already work.

The Takeaway: From Breakdowns to Breakthroughs

Predictive maintenance isn’t just about equipment—it’s about reliability, efficiency, and peace of mind.

When I look at our most successful clients, the common thread isn’t luck—it’s proactive habits. They don’t wait for perfect data or perfect timing; they start small, learn fast, and let insight compound.

Want to put these steps into action? Download the Predictive Maintenance Checklist to evaluate your maintenance process and uncover opportunities for cost savings before your next busy season.

With TapGoods’ built-in intelligence, TapWise, you can see performance trends across your fleet, identify risks early, and keep your equipment earning longer.

Book a demo and get a free trial today to experience TapWise in action.

Other blogs you may find helpful

- Demand Forecasting with AI for Rental Companies

- How AI Improves Customer Experience in Rentals – Coming Soon

- AI-Powered Reporting vs. Traditional Reporting

- The Future of AI in the Rental Industry – Coming Soon

- How AI is Transforming the Rental Business